10.7. Sizing code of an inductor with surrogate models#

Written by Marc Budinger, INSA Toulouse, France

The previous study showed some shortcomings such as not taking into account the thermal and a limitation on the dimensions of the air gap. We will see here how to set up surrogate models from thermal or magnetic finite element simulations.

10.7.1. Thermal configuration description#

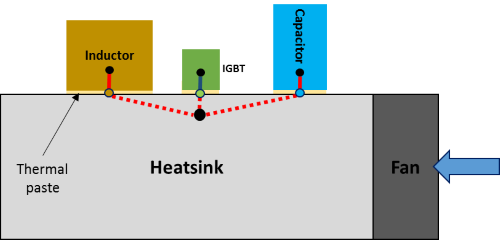

In the previous notebook, the current density \(J\) was imposed. It would be more accurate to calculate the temperature of the hot point of the winding and adjust the value of this current density to limit, for example at 150 ° C, this temperature. The cooling architecture of the various components of the converter takes the following form in this study:

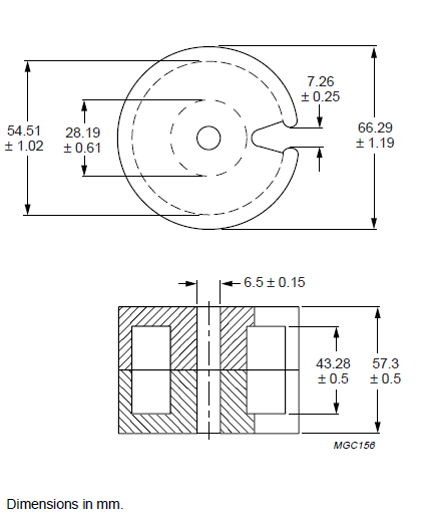

In order to carry out finite element simulations in 2D, we will work on a P-type core which presents a symmetry of revolution.

Other forms of ferrite cores can be found here.

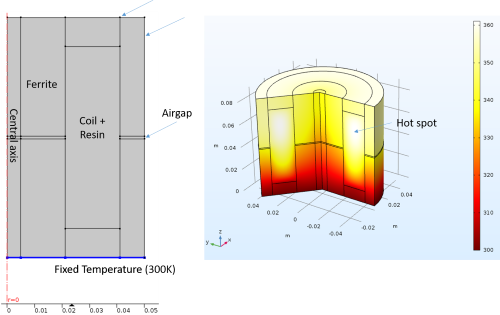

We will assume here to calculate the temperature of the hot spot of the winding:

that temparature of the pot base is fixed

that the convective heat transfer is negligible

that the winding can be represented by an equivalent thermal conductivity

The following table shows some simulation results for different materials configurations and the same level of loss (36W into the coil, 100 mm for the external diameter of the core, 1 mm of airgap). These simulations show that the heat transfer can be optimized in a technological way. We will use the configuration (3), the most effective, for next calculations.

Central Axis |

Airgap |

Hot spot Temperature |

|---|---|---|

Air |

Air |

122 °C |

Air |

Resin |

90 °C |

Aluminum |

Resin |

61 °C |

10.7.2. Buckingham theorem and dimensional analysis#

FEM simulations can take computational time not compatible with design optimization and design space exploration. One way of reducing this computational time is by constructing approximation models, known as surrogate models, response surface models or metamodels.

In order to reduce the number of variables to manipulate during analysises, dimensional analysis and the Buckingham theorem can be used.

We want to find a surrogate model which enable to caculate the thermal resistance between the hot spot of the coil and the support of the core:

\(R_{th}=f(D,e,...,\lambda_{eq},\lambda_{ferrite},...)\)

with:

\(D,e,...\) : the diameter of the pot core, the airgap thickness, other geometrical dimensions. Ferrites cores follow geometrical similarities except for the airgap.

\(\lambda_{eq},\lambda_{ferrite},...\) : the equivalent thermal conductivity of the coil and the other thermal conductivities.

Exercice 1: reduce the number of variables to manipulate with the Buckingham theorem. Give expression of \(\pi_i\) numbers.

Exercice 2: Justify your dimensional analysis with the following FEM results.

Diameter \(D\) |

Copper losses |

Airgap \(e\) |

Eequivalent thermal conductivity (coil) |

Temperature difference \(\Delta \Teta\) |

|

|---|---|---|---|---|---|

1 |

100 mm |

36 W |

1 mm |

0.5 W/(mK) |

61 °C |

2 |

50 mm |

4.5 W |

0.5 mm |

0.5 W/(mK) |

15.3 °C |

3 |

50 mm |

4.5 W |

0.5 mm |

1 W/(mK) |

12.9 °C |

10.7.3. Surface response model for the thermal resistance#

Multiple FEM simulations have been performed. The following file summurizes usefull data:

# Import FEM thermal simulations results

# Panda package Importation

import pandas as pd

# Read the .csv file with bearing data

path='https://raw.githubusercontent.com/SizingLab/sizing_course/main/laboratories/Lab-watt_project/assets/data/'

dHS = pd.read_csv(path+'InductorThermalSurrogate.csv', sep=';')

# Print the head (first lines of the file)

dHS

| D | Lambda | P | T | DT | Rth | PI0=Rth.Lambda.D | PI1=e/D | |

|---|---|---|---|---|---|---|---|---|

| 0 | 0.1 | 0.5 | 35.852 | 356.15 | 56.15 | 1.566161 | 0.078308 | 0.001000 |

| 1 | 0.1 | 0.5 | 35.884 | 356.55 | 56.55 | 1.575911 | 0.078796 | 0.001585 |

| 2 | 0.1 | 0.5 | 35.935 | 357.16 | 57.16 | 1.590650 | 0.079532 | 0.002512 |

| 3 | 0.1 | 0.5 | 36.016 | 358.06 | 58.06 | 1.612061 | 0.080603 | 0.003981 |

| 4 | 0.1 | 0.5 | 36.143 | 359.38 | 59.38 | 1.642918 | 0.082146 | 0.006310 |

| 5 | 0.1 | 0.5 | 36.346 | 361.28 | 61.28 | 1.686018 | 0.084301 | 0.010000 |

| 6 | 0.1 | 0.5 | 36.666 | 363.95 | 63.95 | 1.744123 | 0.087206 | 0.015849 |

| 7 | 0.1 | 0.5 | 37.175 | 367.67 | 67.67 | 1.820309 | 0.091015 | 0.025119 |

| 8 | 0.1 | 0.5 | 37.980 | 372.89 | 72.89 | 1.919168 | 0.095958 | 0.039811 |

| 9 | 0.1 | 0.5 | 39.257 | 380.45 | 80.45 | 2.049316 | 0.102466 | 0.063096 |

| 10 | 0.1 | 0.5 | 41.280 | 391.55 | 91.55 | 2.217781 | 0.110889 | 0.100000 |

We want to perform here a linear regression to determine an estimation model of polynomial form.

Exercice: Perform this multiple linear regression with the StatsModels package and dedicated transformations.

# Determination of the least squares estimator with the OLS function

# of the SatsModels package

import scipy.signal.signaltools

def _centered(arr, newsize):

# Return the center newsize portion of the array.

newsize = np.asarray(newsize)

currsize = np.array(arr.shape)

startind = (currsize - newsize) // 2

endind = startind + newsize

myslice = [slice(startind[k], endind[k]) for k in range(len(endind))]

return arr[tuple(myslice)]

scipy.signal.signaltools._centered = _centered

import numpy as np

import statsmodels.api as sm

# Generation of Y and X matrix

YHS=dHS['PI0=Rth.Lambda.D'].values

YHS=YHS.reshape((np.size(YHS),1))

XHS=np.transpose(np.array((np.ones(np.size(dHS['PI1=e/D'].values)), dHS['PI1=e/D'].values, (dHS['PI1=e/D'].values)**2)))

# OLS regression

modelHS = sm.OLS(YHS, XHS)

resultHS = modelHS.fit()

# Results print

print('Parameters: ', resultHS.params)

print('R2: %.3f'% resultHS.rsquared)

print('The estimation function is: PI0 = %.3g + %.3g PI1 + %.3g PI1^2'

%(resultHS.params[0],resultHS.params[1],resultHS.params[2]))

Parameters: [ 0.0785531 0.52392117 -2.04263184]

R2: 0.997

The estimation function is: PI0 = 0.0786 + 0.524 PI1 + -2.04 PI1^2

10.7.4. Surrogate magnetic model for inductance#

The same approcach can be adopted for magnetic simulations. The model has to take in account the magnetic field in the airgap for small and big values, and using finite elements simulations the proportion of the magnetic field outside the magnetic circuit is also considered. These effects are not well modelled by classical analytic models.

The inductance is represented by the reluctance of the magnetic circuit \(R_L\): \(L=n^2/R_L\), where \(L\) is the inductance, \(n\) the number of turns.

Two assumptions are considered for the study:

The reluctance of the ferrite magnetic circuit is considered during the FEM simulation but neglected for the final expression.

The saturation effects are not considered.

Regression on FEM simulation data with log transformation give the following expression:

\(R_L=\frac{3.86}{μ_0D}π_1^{0.344-0.226 log(π_1)-0.0355 log(π_1)}\)

,where \(π_1=e/D\).

10.7.5. Inductor sizing code#

Exercice: adapt the sizing code of the previous notebook in order to take into account the 2 surrogate models.

%%writefile sizing_inductor.py

import numpy as np

import scipy

import scipy.optimize

from math import pi, sqrt

import timeit

# Specifications

IL_max=150 # [A] max current

IL_RMS=140 # [A] RMS current

L=150e-6 # [H] Inductance

# Assumptions

#J=5e6 # [A/m²] Current density

B_mag=0.4 # [T] Induction

k_bob=0.33 # [-] winding coefficient

T_amb=60 # [°C] Support temperature

T_max=150 # [°C] Max temperature

# Physical constants

mu_0=4*3.14e-7 # [SI] permeability

# Reference parameters for scaling laws (Pot core)

D_ref=66.29e-3 # [m] External diameter

H_ref=57.3e-3/2 # [m] 1 half core height

Airon_ref=pi/4*(29.19**2-6.5**2)*1e-6 # [m^2] iron surface

Awind_ref=43.28*(54.51-28.19)/2*1e-6 # [m^2] winding surface

Rmoy_ref=(54.51-28.19)/2*1e-3 # [m] Mean radius for winding

M_ref=225e-3 # [kg] 1 half core mass

# -----------------------

# sizing code

# -----------------------

# inputs:

# - param: optimisation variables vector

# - arg: selection of output

# output:

# - objective if arg='Obj', problem characteristics if arg='Prt', constraints other else

def SizingInductor(param, arg):

# Variables

e_D=param[0] # [m] air gap / External diameter

J=param[1]*1e6 # [A/m²] current density

# Magnetic pi_0

PI0_m=3.86*e_D**(0.344-0.226*np.log10(e_D)-0.0355*(np.log10(e_D))**2)

# Magnetic energy calculation

E_mag=1/2*L*IL_max**2 # [J] Energy

D=(E_mag*2*PI0_m*D_ref**4/J**2/k_bob**2/Awind_ref**2/mu_0)**(1/5) # External diameter calculation

# Reluctance and inductance

RL=PI0_m/mu_0/D # [] reluctance

N=np.sqrt(L*RL) # [-] turn number

# Wire section & winding surface

S_w=IL_RMS/J # [m²] 1 wire section area

S_bob=N*S_w/k_bob # [m^2] winding surface

# Core scaling

A_iron=Airon_ref*(D/D_ref)**(2) # [m^2] iron surface

A_wind=Awind_ref*(D/D_ref)**(2) # [m^2] winding surface

H=H_ref*(D/D_ref)**(1) # [m] 1 half core height

Rmoy=Rmoy_ref*(D/D_ref)**(1) # [m] Mean radius for winding

M_core =M_ref*(D/D_ref)**(3) # [kg] one half core mass

# Magnetic field

B=N*IL_max/RL/A_iron # [T]

# Mass

M_copper=2*pi*Rmoy*N*S_w*7800

M_total=M_copper+M_core*2

# Temperature calculation

PI0_t = 0.0786 + 0.524*e_D -2.04*e_D**2 # PI0 thermal

Rth=PI0_t/(0.5*D) # [K/W] thermal resistance

PJ=J**2*2*pi*Rmoy*N*S_w*1.7e-8 # [W] Joules losses

Teta_hot=T_amb + PJ*Rth # [°C] Hot spot temperature

# Objective and contraints

if arg=='Obj':

return M_total

elif arg=='Prt':

print("* Optimisation variables:")

print(" Airgap e/D = %.2g"% (e_D))

print(" Current dendity J = %.2g"% (J))

print("* Components characteristics:")

print(" Core (2) mass = %.2f kg" % (2*M_core))

print(" Coil mass = %.2f kg" % M_copper)

print(" Core dimensions = %.1f (diameter) x %.1f (heigth) mm"%((D*1e3,2*H*1e3)))

print(" Airgap e = %.1f mm"%(e_D*D*1e3))

print(" A_iron = %.0f mm^2"%(A_iron*1e6))

print(" Number of turns = %i"%(N))

print("* Constraints (should be >0):")

print(" Winding surface margin = %.3f mm²" % ((A_wind-S_bob)*1e6))

print(" Induction margin = %.3f T" %((B_mag-B)))

print(" Temperature margin = %.3f K" %(T_max-Teta_hot))

else:

return [A_wind-S_bob, B_mag-B, T_max-Teta_hot]

Writing sizing_inductor.py

%run sizing_inductor.py

#Variables d'optimisation

e_D=1e-3 # [m] airgap

J=50 # [A/mm²] current density

# Vector of parameters

parameters = scipy.array((e_D,J))

# Initial characteristics before optimization

print("-----------------------------------------------")

print("Initial characteristics before optimization :")

SizingInductor(parameters, 'Prt')

print("-----------------------------------------------")

# optimization with SLSQP algorithm

contrainte=lambda x: SizingInductor(x, 'Const')

objectif=lambda x: SizingInductor(x, 'Obj')

result = scipy.optimize.fmin_slsqp(func=objectif, x0=parameters,

bounds=[(1e-3,1e-1),(1,50)],

f_ieqcons=contrainte, iter=100, acc=1e-6)

# Final characteristics after optimization

print("-----------------------------------------------")

print("Final characteristics after optimization :")

SizingInductor(result, 'Prt')

print("-----------------------------------------------")

---------------------------------------------------------------------------

KeyError Traceback (most recent call last)

File /opt/hostedtoolcache/Python/3.9.25/x64/lib/python3.9/site-packages/scipy/__init__.py:137, in __getattr__(name)

136 try:

--> 137 return globals()[name]

138 except KeyError:

KeyError: 'array'

During handling of the above exception, another exception occurred:

AttributeError Traceback (most recent call last)

Cell In[4], line 10

5 J=50 # [A/mm²] current density

8 # Vector of parameters

---> 10 parameters = scipy.array((e_D,J))

12 # Initial characteristics before optimization

13 print("-----------------------------------------------")

File /opt/hostedtoolcache/Python/3.9.25/x64/lib/python3.9/site-packages/scipy/__init__.py:139, in __getattr__(name)

137 return globals()[name]

138 except KeyError:

--> 139 raise AttributeError(

140 f"Module 'scipy' has no attribute '{name}'"

141 )

AttributeError: Module 'scipy' has no attribute 'array'

10.7.6. Annex : thermal conductivity#

Material |

Thermal conductivity |

|---|---|

Copper |

400 W/(mK) |

Aluminum |

200 W/(mK) |

Air |

0.03 W/(mK) |

Ferrite |

5 W/(mK) |

Resin |

0.25 W/(mK) |

Copper+Resin(*) |

0.5 W/(mK) |

(*) for a mix of 33% copper, 66% resin