10.8. Design graphs for the sizing a DC/DC converter#

Written by Marc Budinger, INSA Toulouse, France

The purpose of this notebook is to structure the sizing procedure of the DC / DC converter.

In general, the establishment of a sizing procedure involves the resultion of the following 3 problems:

a set of equations sub-constrained by the addition of a design variable in the optimization problem;

an over-constrained variable by adding a design variable (multiplier) and the transfer of the excess equation(s) in the constrained part of the optimization problem;

an algebraic loop by the use of a simplify equation weighted by a multiplying coefficient and a constraint representing the initial equation.

Where possible:

the design variables must take the form of a normalized variable around 1 (oversize coef. for example) or easily bounded to facilitate the work of the optimization algorithm.

the constraints must take the form of inequality and not of equality more difficult to manage. The optimization of the objective (for example the total mass) will certainly force some (active) constraints to come to an end.

10.8.1. Means objective network#

The purpose of the sizing will be to minimize the mass of the converter. The following graph shows that this mass depends mainly on the losses of the converter by the mass of the dissipator. The switching frequency also influences the mass of the filtering portion of the converter and the switching losses. The latter will therefore be chosen as an optimization variable.

Means objective network:

10.8.2. Thermal sizing scenario#

10.8.2.1. Design graph#

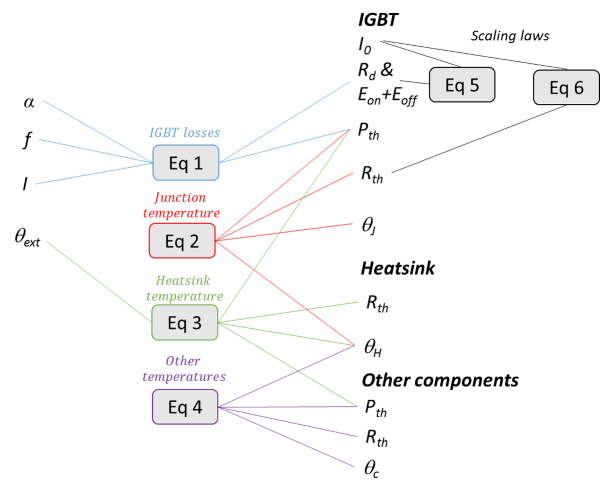

The following figure shows the design graph of a part of the equations representing the calculation of the temperatures of the various components of the DC/DC converter.

Exercise: analyze the design graph and show that there is an algebraic-loop and over-constraints. Propose solutions for these problems.

10.8.2.2. Optimization problem: synthesis#

Exercice: synthesis here the design variables and the constraints which have to be add to the DC/DC converter optimization problem.

10.8.2.3. Sizing code and optimization#

Exercice: propose a sizing code and a optimization loop for the selection of an IGBT module & a heatsink.

The specifications and design assumptions are the following:

# DC/DC converter Specifications

E=150 # [V] DC bus voltage

IL=140 # [A] DC current of the load

UL=62.25 # [V] DC voltage of the load

# Design Assumptions

T_amb=40 # [°C] Ambient temperature

DE=E*.01 # [V] Max ripple voltage DC bus

DIL=IL*.35 # [A] Max ripple current

f=10e3 # [Hz] switching frequency

Lhs=150 # [mm] Heatsink length

For the technical data about the IGBT switchs you have here an example of datasheet for a reference component.

10.8.2.3.1. IGBT#

Scaling laws |

References |

|

|---|---|---|

Definition parameter : |

||

Current |

\(I\) |

\(80 A\) |

Maximum voltage |

\(V_{max}^* = 1\) |

\(900 V\) |

Voltage drop |

\(V_0^*=1\) |

\(1 V\) |

Dynamic resistance |

\(R_0^*=I^{*-1}\) |

20 m\({\Omega}\) |

Commutation losses |

\((E_{on}+E_{off})^*=I^* E^*\) |

\(8.2 mJ\) for \(E=450 V\) |

Thermal resistance |

\(R_{th_JC}^*=I^{*-1}\) |

\(0.30 °C/W\) |

10.8.2.3.2. Diode (Current evolution equal to IGBT current)#

Scaling laws |

References |

|

|---|---|---|

Definition parameter : |

||

Current |

\(I\) |

\(41 A\) |

Maximum voltage |

\(V_{max}^* = 1\) |

\(900 V\) |

Voltage drop |

\(V_0^*=1\) |

\(1 V\) |

Dynamic resistance |

\(R_0^*=I^{*-1}\) |

\(15 m\Omega\) |

Commutation losses |

\(t_{rr}I_{RM}^{*}=I^*E^*\) |

\(17.2 mJ\) for \(E=600 V\) |

Thermal resistance |

\(R_{th_JC}^{*}=I^{*-1}\) |

\(0.47 °C/W\) |

More details about the technical informations can be found here.

The following table summarizes the equations which enable to calculate losses in the main components of the converter.

Inductor |

IGBT |

Diode |

DC Capacitor |

|

|---|---|---|---|---|

Mean current |

\(I_L\) |

\(\alpha I_L\) |

\((1-\alpha)I_L\) |

0 |

RMS current |

\(I_{L,RMS}\) |

\(\sqrt{\alpha } I_{L,RMS}\) |

\(\sqrt{1-\alpha } I_{L,RMS}\) |

\(\sqrt{\alpha \left(1-\alpha \right)} I_{L,RMS}\) |

Conduction losses |

\(R_{L}I_{RMS}^{2}\) |

\({V_{0}}{I_{mean}}+R_{0}I_{RMS}^{2}\) |

\({V_{0}}{I_{mean}}+R_{0}I_{RMS}^{2}\) |

\(R_{S}I_{RMS}^{2}\) |

Commutation losse |

0 |

\(f(E_{on}+E_{off})\) |

\(\frac{1}{8} f I_{RM} E t_{rr}\) |

0 |

with : \(I_{L,RMS}=I_{L}\sqrt{1+\frac{1}{12}\left(\frac{\Delta I_{L}}{I_{L}}\right)^{2}}\)

import numpy as np

import scipy

import scipy.optimize

from math import pi, sqrt

import timeit

def SizingDCDC(param, arg):

# Variables

# ----------------------------------------

#-

T_H=param[0] # [°C] Heatsink temperature (Heatsink)

#-

k_IGBT=param[1] # [-] Oversizing coefficient (IGBT)

# Main electrical equations

# ----------------------------------------

# Global

Alpha=UL/E # [-] Duty cycle

T=1/f # [s] PWM period

# RMS and mean value

IL_max = IL + DIL/2 # [A] Max current (load side) Inductor

IL_RMS = IL*sqrt(1+1/12*(DIL/IL)**2) # [A] RMS current (load side) Inductor

I_IGBT_RMS=sqrt(Alpha)*IL_RMS # [A] RMS current IGBT

I_IGBT_mean=Alpha*IL # [A] mean current IGBT

I_Diode_RMS=sqrt(1-Alpha)*IL_RMS # [A] RMS current Diode

I_Diode_mean=(1-Alpha)*IL # [A] mean current Diode

# ----------------------------------------

# IGBT module IXYS: 900V max

I_IGBT_ref=80 # [A] Ref Current of the module

V0_IGBT_ref=1 #[V] voltage drop

R0_IGBT_ref=20e-3 # [Ohm] dynamic resistance

Ecom_IGBT_ref=8.2e-3 # [J] commutation energy ref

E_IGBT_ref=450 # [V] ref voltage for commutation loss

Rth_IGBT_ref=0.3 # [°C/W] thermal resistance

T_max_IGBT=120 # [°C] max temeprature

# current estimation

I0=k_IGBT*I_IGBT_RMS

# IGBT scaling

V0_IGBT=V0_IGBT_ref #[V] voltage drop

R0_IGBT=R0_IGBT_ref*(I0/I_IGBT_ref)**(-1) # [Ohm] R0*=I*^-1

Ecom_IGBT=Ecom_IGBT_ref*(I0*E/(I_IGBT_ref*E_IGBT_ref)) # [J] commutation energy (Eon+Eoff)*=I*E*

Rth_IGBT=Rth_IGBT_ref*(I0/I_IGBT_ref)**(-1) # [°/W] Rth*=I*^(-1)

# Thermal calculation

Ploss_IGBT=V0_IGBT*I_IGBT_mean+R0_IGBT*I_IGBT_RMS**2+f*Ecom_IGBT # [W] IGBT losses

T_hot_IGBT=T_H + Ploss_IGBT*Rth_IGBT # [°C] IGBT junction temperature

# Diode of IGBT module IXYS : 900V max

I_Diode_ref=41 # [A] Ref Current of the module

V0_Diode_ref=1 #[V] voltage drop

R0_Diode_ref=15e-3 # [Ohm] dynamic resistance

QrrE_ref=17.2e-3 # [J] commutation energy

E_Diode_ref=600 # [V] ref voltage for commutation loss

Rth_Diode_ref=0.47 # [°C/W] thermal resistance

# Diode scaling

V0_Diode=V0_Diode_ref #[V] voltage drop

R0_Diode=R0_Diode_ref*(I0/I_IGBT_ref)**(-1) # [Ohm] R0*=I*^-1

QrrE=QrrE_ref*(I0*E/(I_IGBT_ref*E_Diode_ref)) # [J] commutation energy (trrIrm)*=I*E*

Rth_Diode=Rth_Diode_ref*(I0/I_IGBT_ref)**(-1) # [°/W] Rth*=I*^(-1)

# Thermal calculation

Ploss_Diode=V0_Diode*I_Diode_mean+R0_Diode*I_Diode_RMS**2+f*QrrE # [W] Diode losses

T_hot_Diode=T_H + Ploss_Diode*Rth_Diode # [°C] Hot spot temperature

# ----------------------------------------

# Heatsink : forced convection (2m/s)

# Rth,f = 150*W**(-0.85)*H**(-0.62)*36.7*L**(-0.72) # [°/W] thermal resistance with W,H,L in mm

# Rth,f = 5505*H**(-1.47)*W_H**(-0.85)*L**(-0.72)

RthH=(T_H-T_amb)/(Ploss_Diode+Ploss_IGBT) # [°/W] Thermal resistance target

# Objective and contraints

if arg=='Obj':

return 1/RthH

elif arg=='Prt':

print("* Assumptions:")

print(" Frequency f= %.2e Hz"%(f))

print(" Ripple current DIL/IL= %.2f %%"%(DIL/IL*100))

print("* Optimisation variables:")

print(" Heatsink temperature (Heatsink) T_H= %.2f [°C]"%(T_H))

print(" Oversizing coefficient (IGBT) k_IGBT= %.2f"%(k_IGBT))

print("* Components characteristics:")

print(" Power = %.2f kW"%(IL*UL/1e3))

print(" Efficiency = %.2f %%"%((IL*UL)/(IL*UL+(Ploss_Diode+Ploss_IGBT))*100))

print(" ---- IGBT + Diode")

print(" Power loss IGBT= %.2f W"%(Ploss_IGBT))

print(" Power loss Diode= %.2f W"%(Ploss_Diode))

print(" ---- Heatsink")

print(" Thermal resistance = %.2f K/W"%(RthH))

print("* Constraints (should be >0):")

print(" Temperature margin IBGT= %.3f K" %(T_max_IGBT-T_hot_IGBT))

print(" Temperature margin Diode= %.3f K" %(T_max_IGBT-T_hot_Diode))

else:

return [T_max_IGBT-T_hot_IGBT,T_max_IGBT-T_hot_Diode]

#Variables d'optimisation

T_H=65 # [°C] Heatsink temperature (Heatsink)

#W_H=.1 # [°C] Width W / Height H aspect ratio (Heatsink)

k_IGBT=1 # [-] Oversizing coefficient (IGBT)

# Vector of parameters

parameters = np.array((T_H,k_IGBT))

# Initial characteristics before optimization

print("-----------------------------------------------")

print("Initial characteristics before optimization :")

SizingDCDC(parameters, 'Prt')

print("-----------------------------------------------")

-----------------------------------------------

Initial characteristics before optimization :

* Assumptions:

Frequency f= 1.00e+04 Hz

Ripple current DIL/IL= 35.00 %

* Optimisation variables:

Heatsink temperature (Heatsink) T_H= 65.00 [°C]

Oversizing coefficient (IGBT) k_IGBT= 1.00

* Components characteristics:

Power = 8.71 kW

Efficiency = 94.39 %

---- IGBT + Diode

Power loss IGBT= 234.11 W

Power loss Diode= 283.96 W

---- Heatsink

Thermal resistance = 0.05 K/W

* Constraints (should be >0):

Temperature margin IBGT= -6.983 K

Temperature margin Diode= -62.784 K

-----------------------------------------------

# Then we can solve the problem and print of the optimized solution:

# In[70]:

# optimization with SLSQP algorithm

contrainte=lambda x: SizingDCDC(x, 'Const')

objectif=lambda x: SizingDCDC(x, 'Obj')

result = scipy.optimize.fmin_slsqp(func=objectif, x0=parameters,

bounds=[(45,95),(1,10)],

f_ieqcons=contrainte, iter=100, acc=1e-8)

# Final characteristics after optimization

print("-----------------------------------------------")

print("Final characteristics after optimization :")

SizingDCDC(result, 'Prt')

print("-----------------------------------------------")

Optimization terminated successfully (Exit mode 0)

Current function value: 11.215106467594092

Iterations: 13

Function evaluations: 41

Gradient evaluations: 13

-----------------------------------------------

Final characteristics after optimization :

* Assumptions:

Frequency f= 1.00e+04 Hz

Ripple current DIL/IL= 35.00 %

* Optimisation variables:

Heatsink temperature (Heatsink) T_H= 85.77 [°C]

Oversizing coefficient (IGBT) k_IGBT= 3.66

* Components characteristics:

Power = 8.71 kW

Efficiency = 94.44 %

---- IGBT + Diode

Power loss IGBT= 211.13 W

Power loss Diode= 302.21 W

---- Heatsink

Thermal resistance = 0.09 K/W

* Constraints (should be >0):

Temperature margin IBGT= 18.965 K

Temperature margin Diode= -0.000 K

-----------------------------------------------

10.8.3. Design graph of the filtering criteria#

The following figure shows the design graph of a part of the equations representing the calculation of voltage and current ripples in the converter. The voltage ripple has a direct impact on the EMC quality of the converter and is limited for example to 1 or 2% of the DC bus voltage.

Note: A more detailed EMC calculation would require a filtering study considering harmonics of current absorbed.

Exercice: analyze the design graph and show that there is an algebraic-loop and a under-constraint.